Understanding how a printer works begins by exploring the key components that make up its internal structure. Every gear, roller, and sensor plays a vital role in transforming digital files into physical documents with precision and clarity. Whether you’re using a laser printer, inkjet printer, or multifunction device, these machines share a common architecture engineered for performance, reliability, and accuracy.

Main Categories of Printer Hardware Components

Printers are composed of several core assemblies that work in harmony to deliver consistent output. These can be divided into the following primary categories:

- Print Engine Components

- Paper Handling Mechanisms

- Ink or Toner Delivery Systems

- Control and Interface Boards

- Sensors and Calibration Tools

- Power Supply and Cooling Systems

Each category includes specialized parts responsible for a distinct task in the print process.

1. Print Engine: The Heart of the Printer

At the core of any printing device lies the print engine, which varies depending on the technology—inkjet or laser.

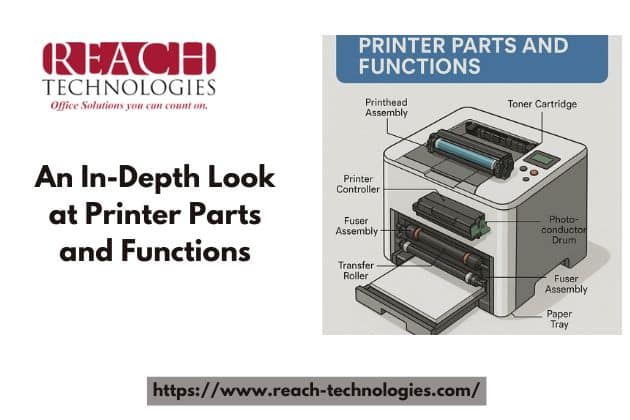

Laser Printer Engine Parts

- Laser Unit: Projects the image onto the photoconductor drum using laser beams.

- Photoconductor Drum: Also called the imaging drum, it receives the laser pattern and attracts toner particles.

- Toner Cartridge: Contains the toner powder and a developer roller that charges and transfers toner to the drum.

- Fuser Assembly: Uses heat and pressure rollers to bond toner to paper permanently.

- Transfer Roller: Transfers toner from the drum to the sheet of paper.

Inkjet Printer Engine Parts

- Printhead: Contains nozzles that spray ink droplets with micrometer precision.

- Cartridge: Houses liquid ink in compartments (cyan, magenta, yellow, black).

- Stepper Motor: Drives the printhead across the page in precise increments.

- Platen Roller: Holds the paper flat as the printhead deposits ink.

2. Paper Handling Mechanisms

Smooth and accurate paper feeding is essential for uninterrupted printing. This is managed by a series of mechanical components:

- Input Tray: Holds blank paper before feeding it into the printer.

- Pick-Up Roller: Pulls one sheet at a time into the paper path.

- Separation Pad: Prevents multiple sheets from feeding simultaneously.

- Registration Rollers: Align and time the sheet before it reaches the print area.

- Output Tray: Collects the printed pages in the correct order.

- Duplexer: Allows for double-sided printing by flipping the paper.

High-end printers may also include paper cassettes, envelope feeders, and stackers for added automation.

3. Ink and Toner Delivery Systems

Each print technology has its unique way of delivering color or black-and-white output.

Inkjet Delivery

- Uses thermal bubble or piezoelectric technology to eject ink through the printhead.

- Each color is stored in separate tanks or combined in a tri-color cartridge.

- Includes cleaning stations and wiper blades to maintain nozzle quality.

Laser Delivery

- Employs electrostatic attraction to apply toner.

- The toner is fused using rollers heated to 200°C+.

- Waste toner bottles collect unused toner from cleaning blades.

4. Controller Board and Firmware

Every modern printer has an embedded logic board that functions as its central nervous system.

- Processor (CPU): Interprets print commands and manages job queues.

- RAM: Temporarily holds print jobs for fast retrieval.

- ROM/Flash Memory: Stores printer firmware and configuration settings.

- Interface Ports: Includes USB, Ethernet, Wi-Fi, and Bluetooth connectivity.

- Embedded Web Server: Enables remote monitoring, job tracking, and diagnostics.

This component handles complex rendering languages such as PCL, PostScript, or PDF Direct Printing.

5. Sensors and Calibration Systems

Modern printers rely heavily on optical, mechanical, and thermal sensors to ensure precise operation.

- Paper Path Sensors: Detect paper presence and movement.

- Cartridge Detection Sensors: Ensure proper installation and alert for low ink or toner.

- Temperature Sensors: Monitor heat levels in the fuser assembly.

- Printhead Alignment Sensors: Automatically adjust printhead positioning.

- Color Calibration Tools: Help maintain accurate output in graphic design and photography environments.

These systems support self-healing print environments that can automatically correct minor mechanical or quality issues.

6. Power and Cooling Infrastructure

To support high-performance output, printers require stable electrical and thermal regulation.

- Power Supply Unit (PSU): Converts AC to DC power and delivers appropriate voltages.

- Cooling Fans: Prevent overheating during large jobs.

- Heatsinks: Dissipate heat from processor units and fuser modules.

- Power Saver Modes: Reduce energy use when idle.

Advanced printers comply with ENERGY STAR® certifications to reduce operational costs and environmental impact.

7. Display Panel and User Interface

Touchscreens and control panels provide an intuitive interface for users and technicians.

- LCD/LED Displays: Show menus, job status, and error messages.

- Navigation Buttons or Touchscreens: Enable control of scan, copy, and fax functions.

- NFC Readers: Authenticate users for secure print jobs using ID cards or smartphones.

- Multilingual Support: Ensures accessibility for global organizations.

Some interfaces also support voice commands, integration with virtual assistants, and cloud-based service portals.

Applications in Managed Print Services (MPS)

Organizations that utilize Managed Print Services benefit from understanding printer parts for better:

- Fleet management

- Proactive maintenance

- Cost analysis

- Device standardization

Through MPS, businesses can monitor the health of every printer part remotely, schedule replacements, and minimize downtime.

Conclusion: Partner with Reach Technologies for Optimized Print Infrastructure

An in-depth understanding of printer components leads to smarter decisions in maintenance, purchasing, and print fleet management. Whether you’re managing a single office or a nationwide print infrastructure, having the right support is critical.

Reach Technologies provides expert guidance and reliable solutions tailored to your print environment. From component-level diagnostics to complete MPS integration, we ensure that every part of your printer performs at its best.

Get in touch with Reach Technologies today to elevate your print environment with expert insight and precision-driven support.